Tartan Spray Paint

Created on 29 Oct 2018

It's just an inkjet printer

Show off your Tartan pride with a can of spray paint that sprays plaid. Plaid is the prettiest color.

@fbasit

Fatima Basit

@lmplotte

Louis Plottel

@rhsin

Rachel Hsin

@huachenw

Tina Wu

@mnowrooz

Mina Nowroozi

| Part | Cost | Quantity | Total |

| Red Spray Paint | $1.50 | 6 | $9.00 |

| Spray Paint for painting | |||

| Green Spray Paint | $6.79 | 4 | $27.16 |

| Spray Paint for painting | |||

| Blue Spray Paint | $6.79 | 4 | $27.16 |

| Spray Paint for painting | |||

| Yellow Spray Paint | $4.69 | 4 | $18.76 |

| Spray Paint for painting | |||

| Motor | $3.50 | 20 | $70.00 |

| makes paint spray | |||

| Arduino Starter Kit | $34.99 | 1 | $34.99 |

| hrlpsbbefbgrbfg | |||

| breadboard wire | $6.98 | 1 | $6.98 |

| wire things together | |||

| Electrical tape | $8.99 | 1 | $8.99 |

| tape things together eleicticrillty | |||

| Duck Tape | $8.99 | 1 | $8.99 |

| hold things together | |||

| rubber bands | $4.87 | 1 | $4.87 |

| hold things together | |||

| arduino | $17.50 | 4 | $70.00 |

| microcontroller and back-ups | |||

| krazy glue | $6.23 | 1 | $6.23 |

| 5 pack kkkkkkkkkkrrrrrraaaaaazzzzzzyyyyyyy | |||

| Project Totals: | 48 | $293.13 | |

| Track 1 Base Budget: | $250.00 | ||

| Preferred Vendor Budget Bonus: | $50.00 | ||

| Remaining Budget: | $6.87 | ||

Rachel Hsin

15 Jan 2019, 8:58 p.m. EST

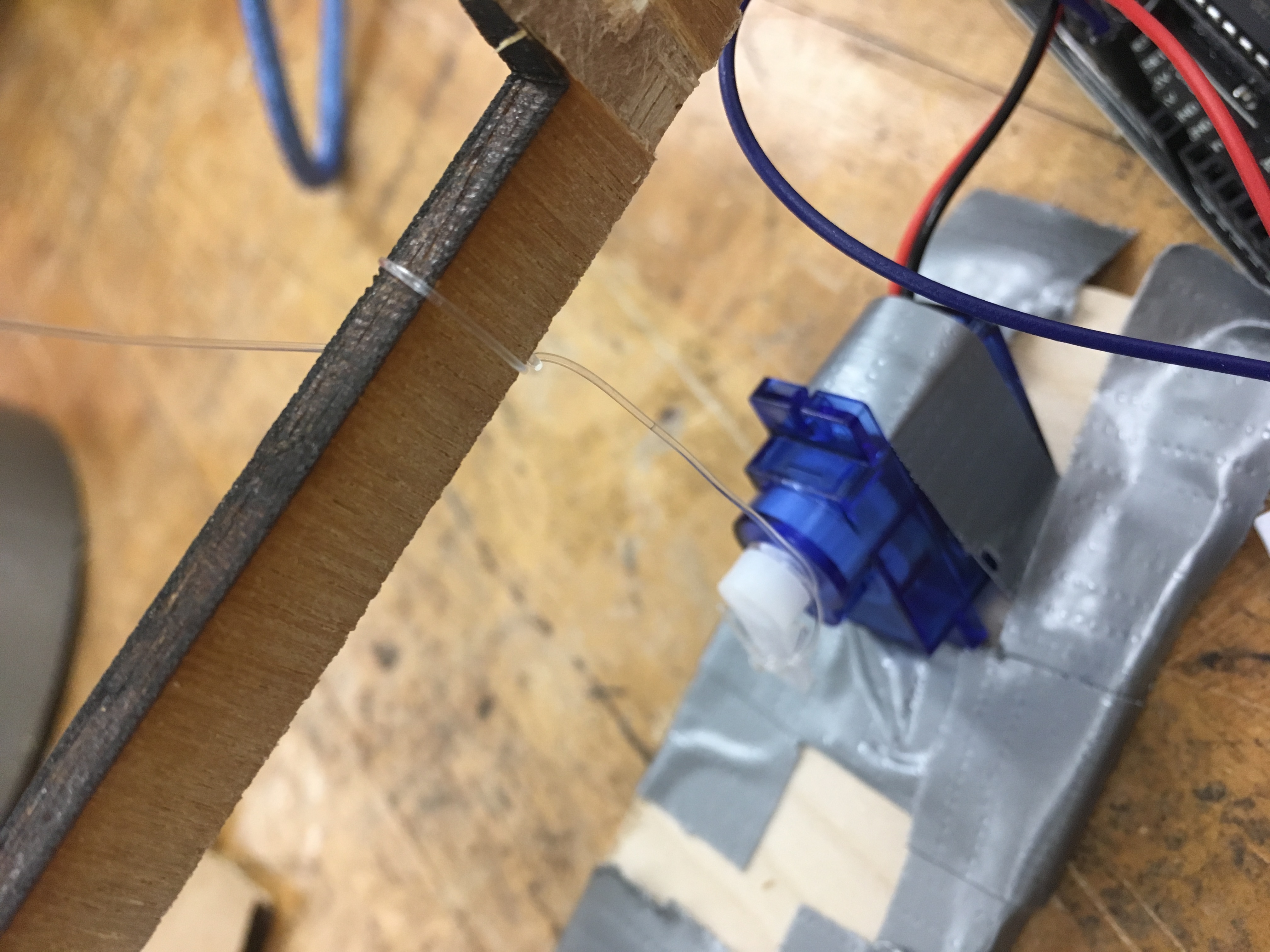

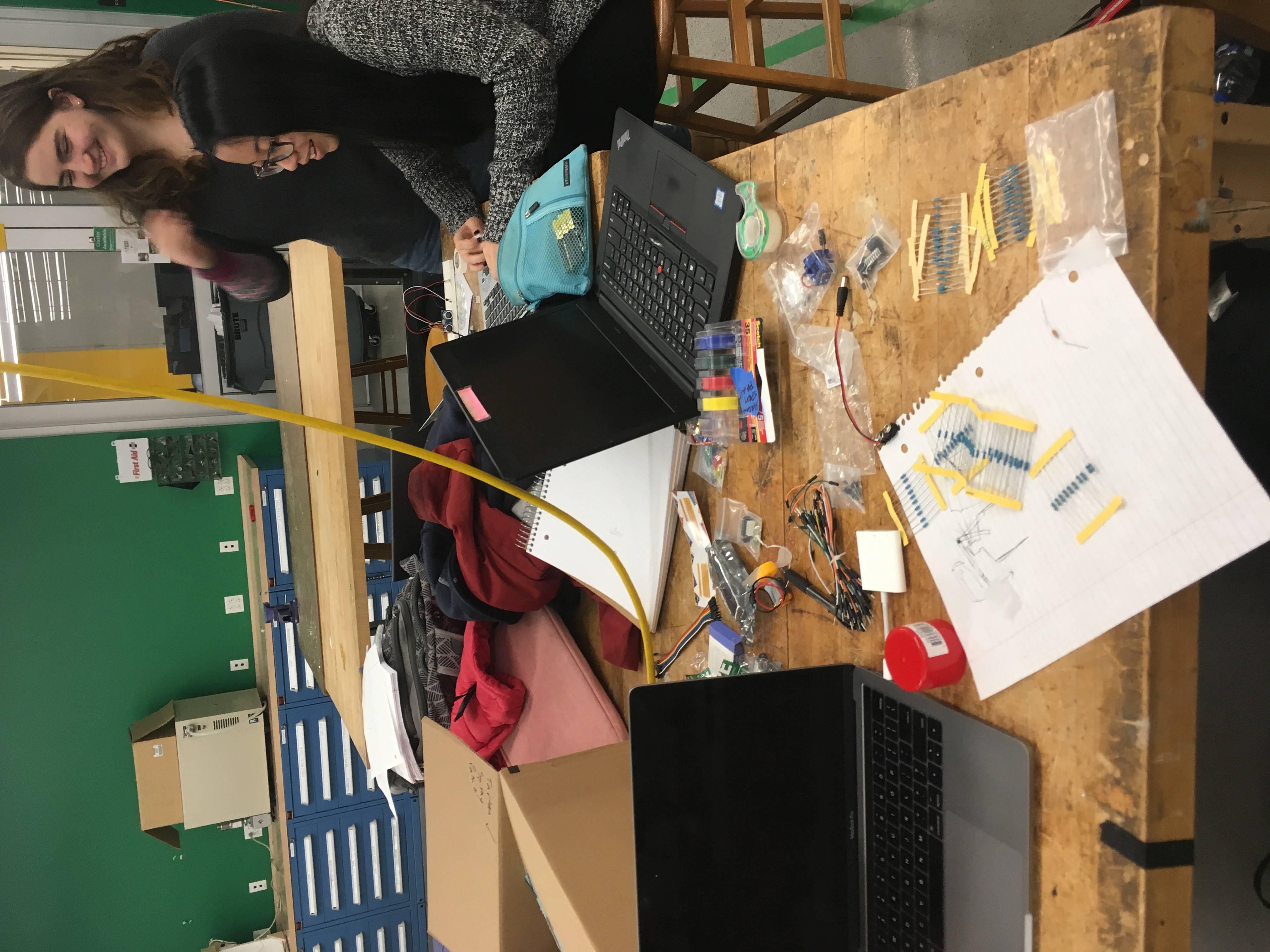

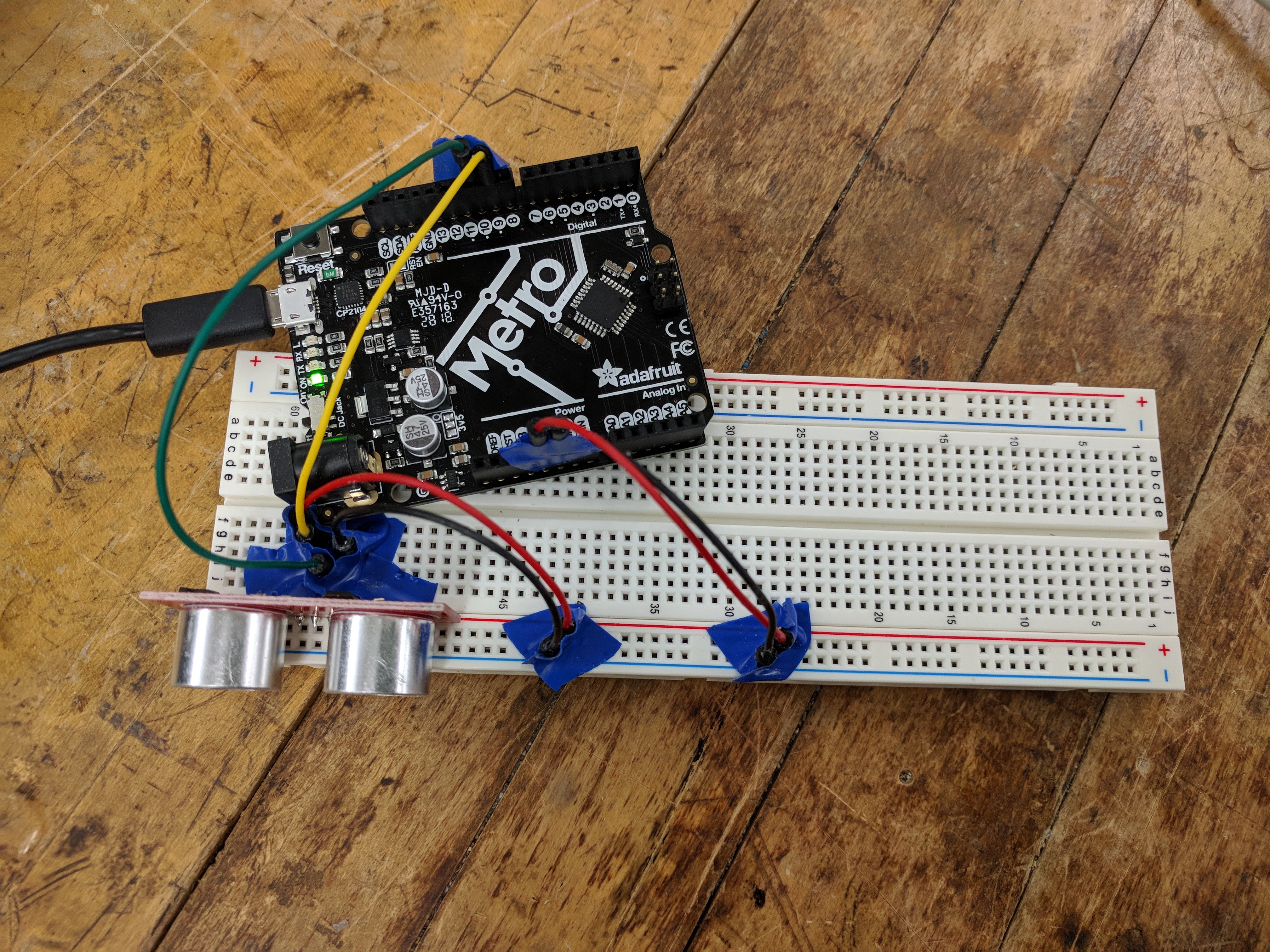

1/14/19 (Monday) - Tested hardware: ran motors, sprayed paint can for reference. Fatima Basit, Louis Plottel, and Rachel Hsin (hardware team) built prototype mount for one spray can using scraps of wood, one large nail, rubber bands, duct tape, fishing line. Wired motor to Arduino Uno, tested using test code from Mina Nowroozi and Tina Wu (software team). Hardware team tested different lever arm lengths to find shortest possible arm that motor could reasonably handle and finished off the night by making CAD to laser cut a complete prototype for a total of sixteen cans in the same assembly. Software team tested and calibrated ultrasonic sensor for returning y-axis position of device. Also developed algorithm for creating tartan pattern when spraying paint arbitrarily.

Tina Wu

16 Jan 2019, 12:23 a.m. EST

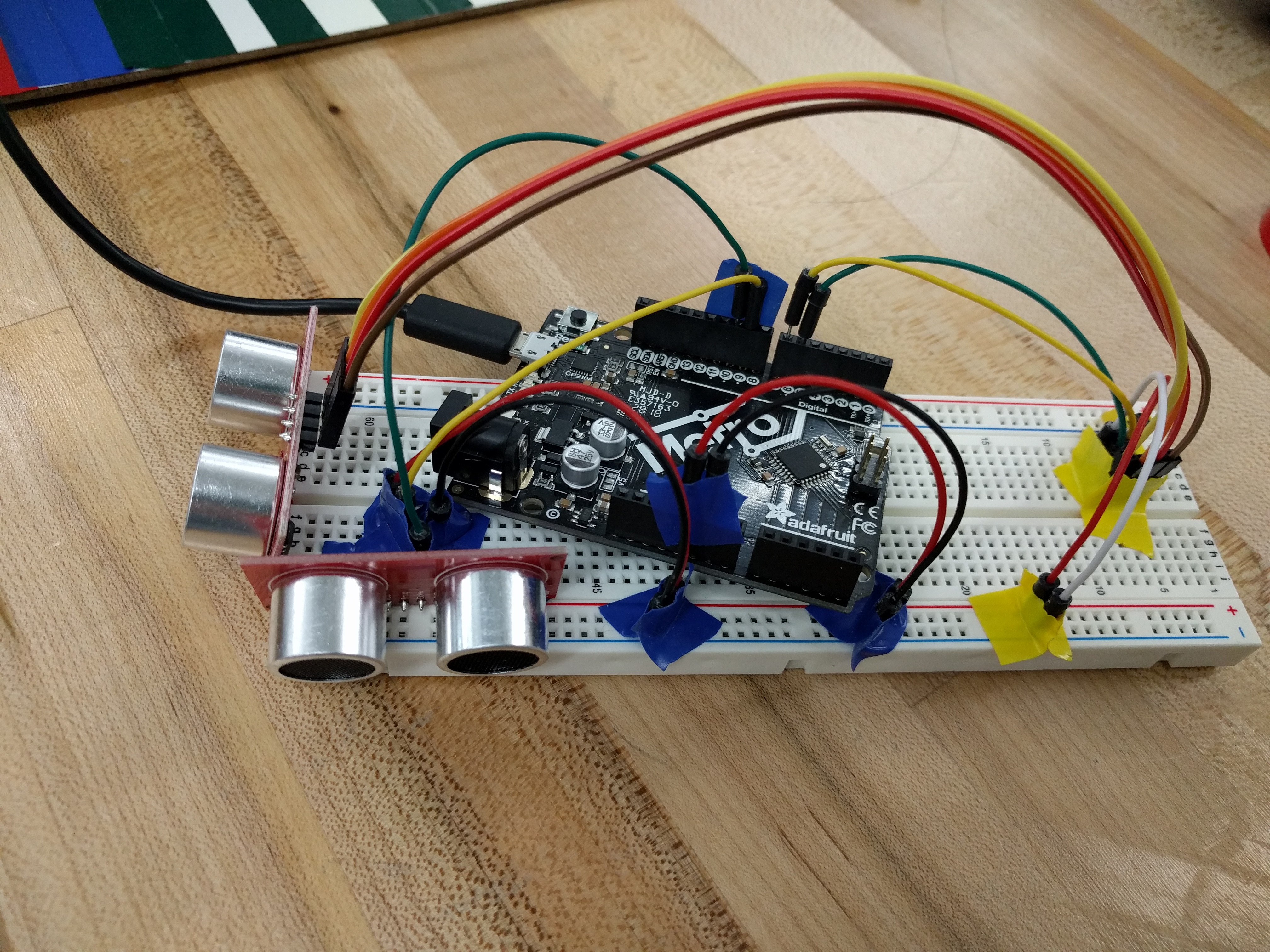

1/15/19 (Tuesday) - The hardware team refined the design of a mount for a single spray can and laser cut acrylic for the mount. They continued testing with motors and different Arduino boards. The software team completed the algorithm to determine the color of the paint needed for a specific (x,y) point (i.e. given a distance of 100 cm from the floor and 90 cm from an adjacent wall, as measured by ultrasonic sensors, should red paint can #2 spray at the wall while in its current location or not?). Additionally, they continued testing the ultrasonic sensors to make sure that their output was sufficiently accurate and consistent.

Mina Nowroozi

16 Jan 2019, 11:33 p.m. EST

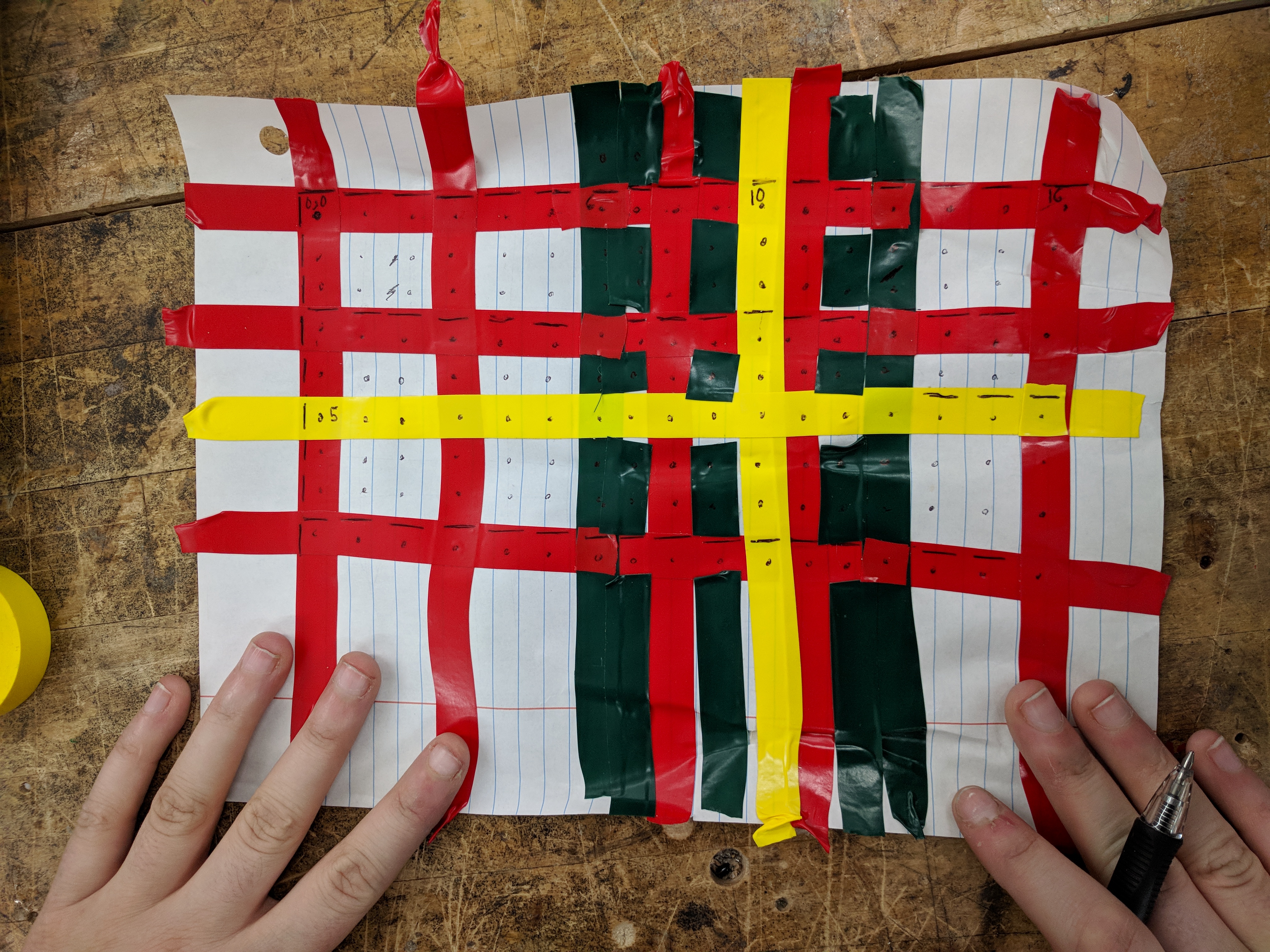

1/16/19 (Wednesday) - The hardware team created CAD and laser cut acrylic for the final frame that will hold the sixteen paint cans. They also tested different nozzle prototypes made from paper to try to reduce the paint spray radius. The software team integrated a second ultrasonic sensor into the arduino setup and completed the code to get from the sensor readings to horizontal and vertical displacement along the tartan pattern. Also, we debugged the high-level code that determines which cans paint from which positions in order to form a relatively even pattern, while allowing for some inherent error / lack of alignment.

Tina Wu

18 Jan 2019, 3:39 a.m. EST

1/17/19 (Thursday) - The hardware team adjusted the frame to hold 4 cans (2x2) instead of 16. The software team ran test code to identify hardware issues causing the paint to not spray when it should have sprayed. We connected the ultrasonic sensors to the same circuit as the motors that make the paint can spray in order to have a complete process from the sensor measurements to the paint spraying. There were still some issues that prevented the device from correctly spraying the tartan pattern, including some mistakes in wiring and misalignment of the rig that pushes the trigger of the paint can.